Production

Our world...

Summary: fabrics, cuts and generalities.

For our sails we use all fabrics available on the market, from Dacron to Dynema.

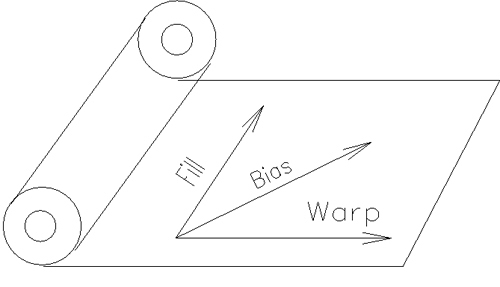

They all have one thing in common: they consist of a weft and a warp, in English called Warp (0°) and Fill (90°), while Bias (45°) is never reinforced by threads like Warp and is therefore the weakest option.

Warp and Fill can be composed of a number of different threads depending on the characteristics requested by the manufacturer.

The Warp oriented is particularly suitable for vertical and radial sails while the Fill oriented for horizontal Cross Cut sails is used in Dacron for both cruising and racing where the regulation prohibits any other types of fibres.

These characteristics are valid for high and narrow sails called High Aspectsails.

In this particular case, the shape of the sails being tall and thin, it generates the most load against the leech, and this is where the Dacron High Aspect gets its best use.

The less a fabric stretches the better!

So we could wonder: why not use a radial cut in Dacron since the load is so strong against the leech?

First of all the Fill orientedfabric is clearly stronger and less stretchy than a Warp oriented one with the same structure and weight, simply because of the weaving which makes the Fill yarn linear whereas the Warp yarn crimps around the Fill yarn.

Under stress the Warp stretches like a mooring strand rope unlike the Fill, which would react like a unidirectional rope, precisely because the yarns are linear and taut.

E.g.: between two Dacron, Warp and Fill of the same weight, the Fill is always stronger and less elastic, and as the load increases this difference often increases exponentially.

Tip: always be wary of Tri-Radial Cut proposals for the mainsails and Genoa jibs in Dacron.

There is always a correlation between the weight of the fabric and its stretching.

It is always better to use the least stretchy fabric for the leech.

Another characteristic is the “starch” in the Dacron, obtained from a coat of synthetic resin which reduces any stretching

The resin-coated Dacron is mainly requested for regatta sails, where other yarns are forbidden due to cost reduction.

We can still find on the market today laminates of Mylar, Pentex, Spectra, Vectran, Kevlar, PBO and Carbon, etc. assembled through a plastic film, which not only holds the fabric together but also improves its mechanical properties and makes it windproof and waterproof.

All the laminates are glued together with adhesives which tend to wear out and create delamination of the fabric eventually leading to the end of the sail.

Indeed, no laminates including the film has been produced yet, which would make the sail resistant to folds, wearing, sun and mould.

Nowadays, the development of new membranes held together by two layers of Taffeta (extremely light Dacron) and without film, with an inner structure chosen and designed by the sail maker, allows the creation of extraordinary light, soft, long-lasting sails, presenting low-stretching characteristics.

Innovation and design

Our sails are technologically advanced and constantly updated.

We are fond of the best equipment and we have never spared any expense by furnishing the boat at its best.

In order to meet any need in terms of materials, dimensions, types of use and design, Andrea Mura Sail Design production area has been set up with leading edge equipment and computer systems:

- a 350 m2 empty surface covered in Okoumé for the processing of sails.

- 6 powerful long arm electro-pneumatic sewing machines embedded in the floor.

- New 12 m long drawing and cutting plotter with carbon arm that cuts at a speed of 1.5 m/sec interfaced to a network of 6 computers with large 4K monitors.

- Constantly updated and sophisticated softwares for the design and cutting of sails.

- Computer network for quick access to the database.